|

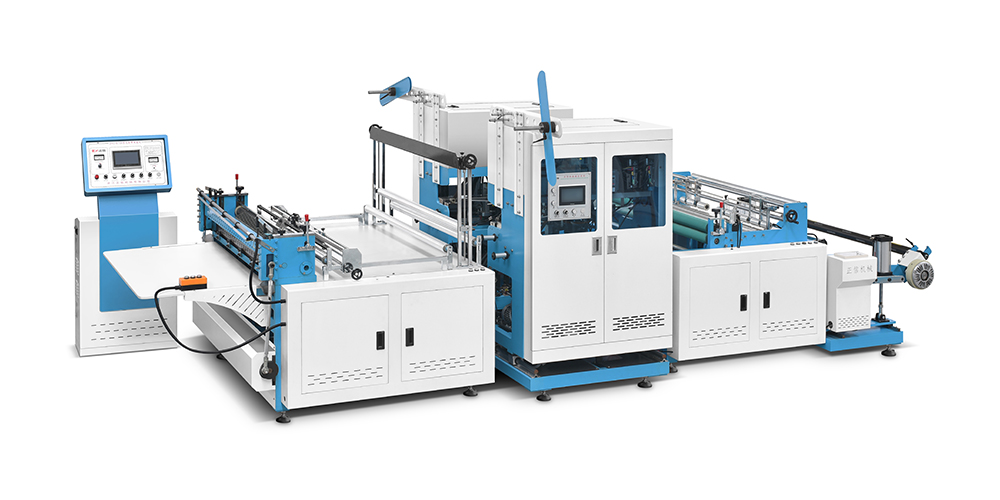

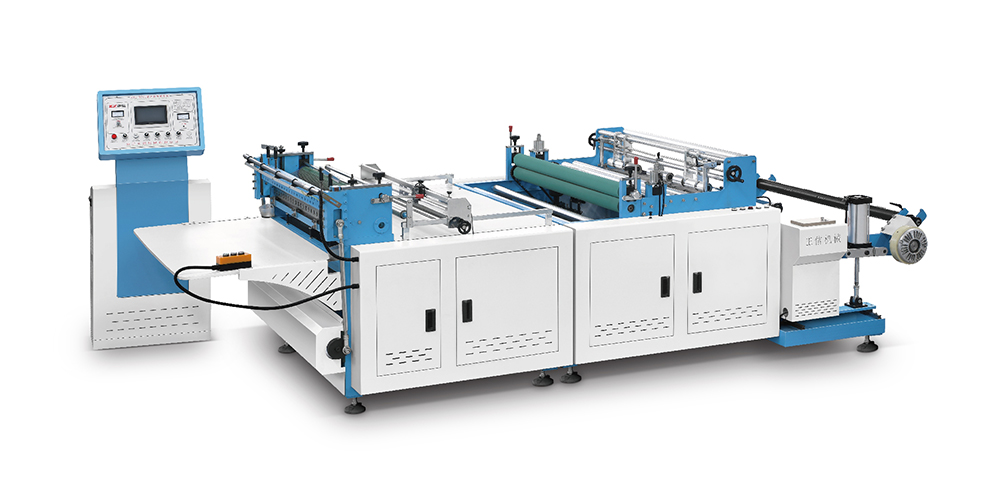

Part 1 Fabric roll Feeding part |

||

|

|

|

|

Equiped with Photocell eye tracking, Auto rectifying deviation, Magnet powder tension control,folding sealing by ultrasonic welding, custom made round embossing mould. |

||

|

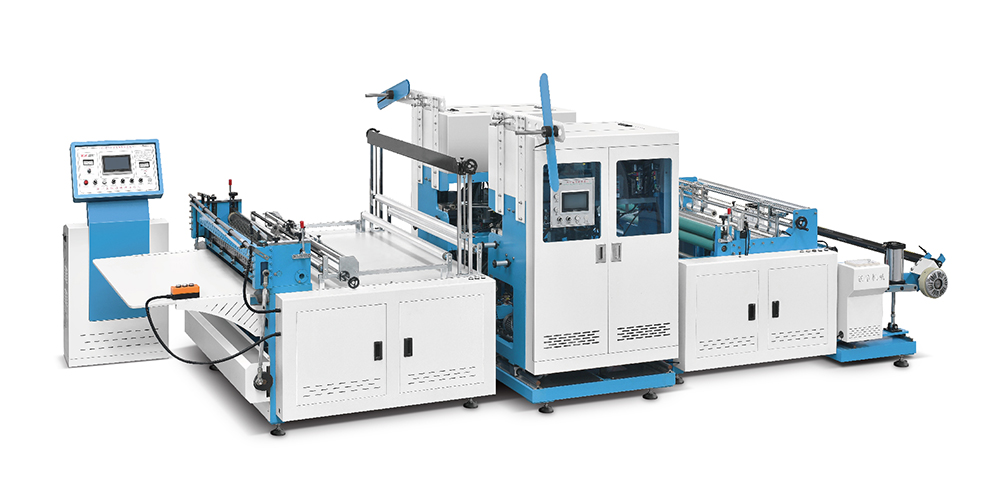

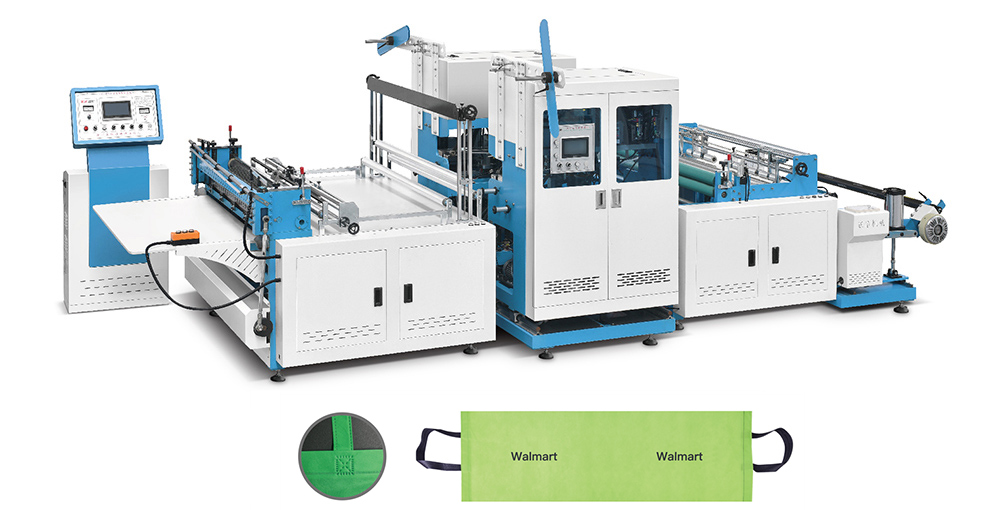

Part 2 Online double side soft handle sealing |

||

|

|

|

|

| The function of welding the double handle loop on the material by 2 side handle sealing machine . it’s mainly used in the producing of manual non woven sealing bag , wine and git bag etc. | ||

|

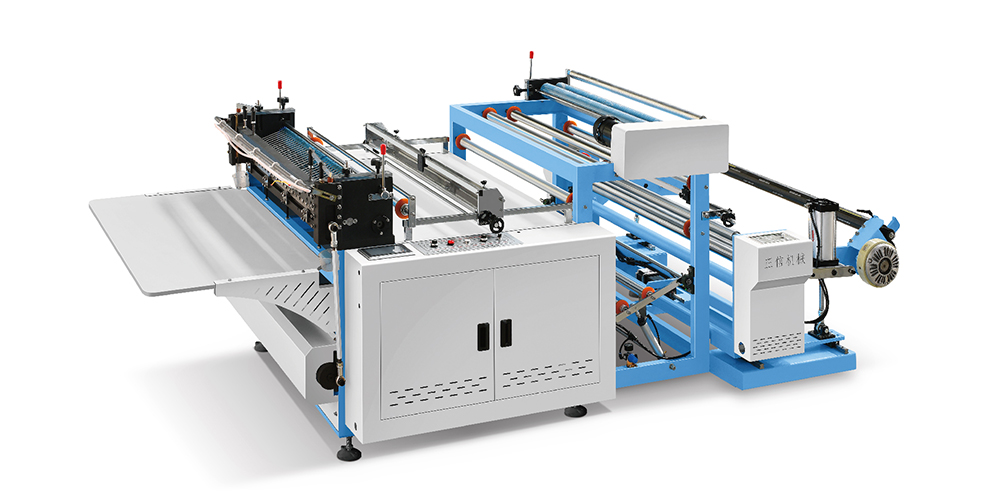

Part 3 Finished product collecting part |

||

|

|

|

| Adopts quality cutting knife , wear-resistant, durable, product cutting is tidy and beautiful. | ||

|

Part 4 Operation Computer |

||

|

|

|

| Integrate all the electricity elements, adopts split-type design and PLC motion control as well as touch screen man-machine interface, easy operation and maintaining. | ||

Machine Parameters:

| Model | ZXQ-C1200 |

| Fabric Roll Width | 500-1250mm |

| Production Speed | 40-100pcs/min |

| Feeding Length | 280-800mm |

| Cutting Width | 500-1200mm |

| Handle Material Thickness | 50-100g/㎡ |

| Handle L ength | 350-600mm |

| Material Thickness | 35-120g/㎡ |

| Voltage | 380V/220v |

| Total Power | 13kw |

| Overall Dimension | 6500x2300x1800mm |

| Weight | 2600kg |